about Us

Company profile

Dongguan Shuoping Electronics Co., Ltd. was established in 2015 and a manufacturing factory was established in 2017, specializing in connector research and development and production.

At present, the factory covers an area of 8000 square meters and has 8 new gantry type punches, 4 imported new KYORI elbow type punches from Japan, 6 imported new Japanese precision high-speed injection molding machines, 60 fully automatic assembly machines, and 50 fully automatic CCD inspection and packaging machines. As of now, the fixed assets of the equipment have exceeded 30 million. The company currently has more than 120 employees, 5 senior product development engineers, 2 automation machine designers, and 20 quality personnel, There are 15 management personnel, with an average age of no more than 35 years old.

At present, the company's main products include floating board to board connectors, power and signal connectors, high-frequency transmission connectors, gold finger slot connectors, board to board connectors, FPC connectors, car connectors, line to board connectors, and other high-precision connectors. We can provide you with a series of electronic product connection solutions!

SOLEPIN firmly believes in continuous research and development and continuous improvement, and invests a large amount of funds annually for research and development and improvement. Every year, new connector products are launched for various industries, and the company has obtained mandatory certification for ISO 9001, ITAF16949, UL, CE, and TUV products. In the coming years, SOLEPIN is determined to become the most reliable strategic partner and will also be a partner worthy of customers' reliance and continuous innovation, research and improvement!

Our advantages

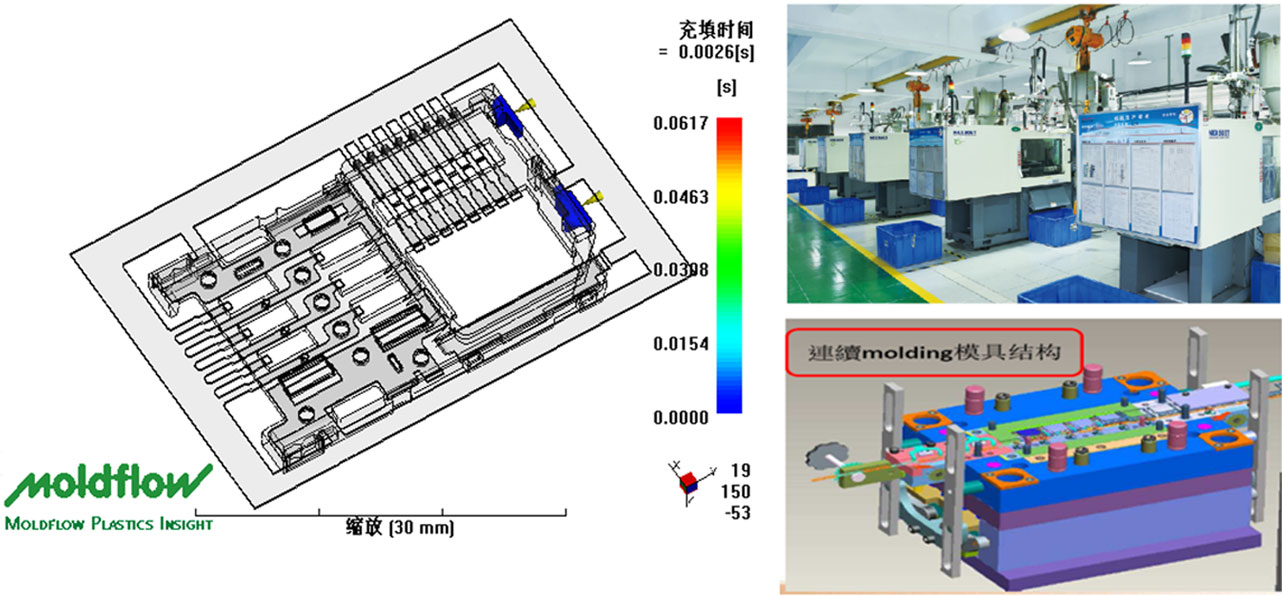

In the plastic mold design stage,Pro-E software is used for modeling and mold flow analysis software Moldflow is used to analyze the plastic flow direction. Combined with line position, warpage deformation direction and flatness, the design is adjusted to ensure product design quality.

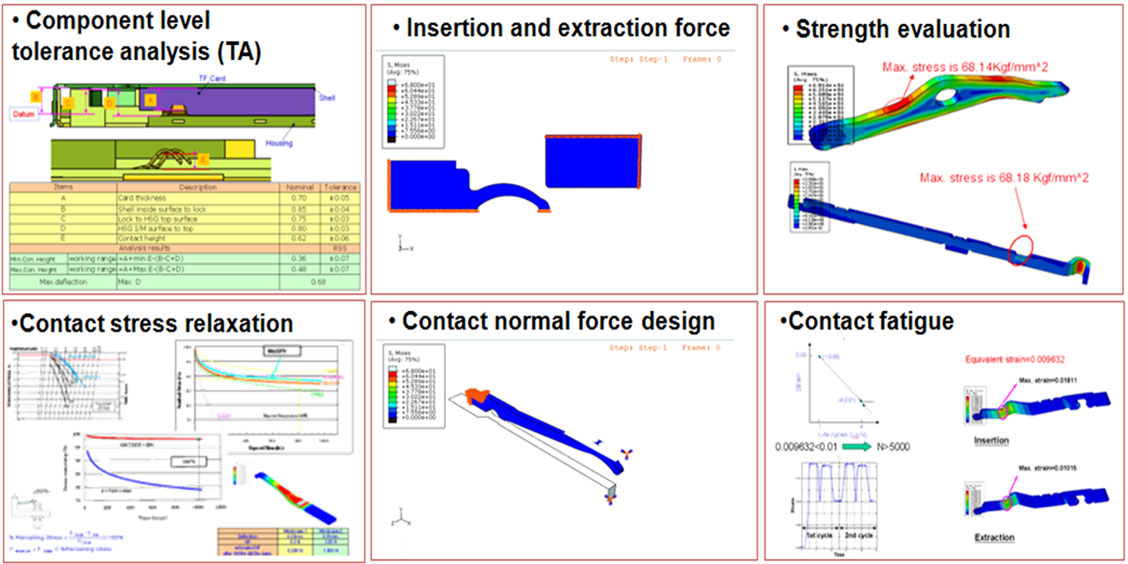

In the early stage of product design, designers use professional spring splinter stress analysis software (ABAQUS) to analyze the maximum stress of the spring splint terminals, predict permanent deformation and positive pressure and adjust the design to the customer's ideal design parameters based on the predicted values to achieve a successful one-time design. The effect is greatly reduced, thereby greatly reducing the possibility of changes after the design is completed, greatly reducing the product design and development cycle, saving product development costs, and making the product more competitive.

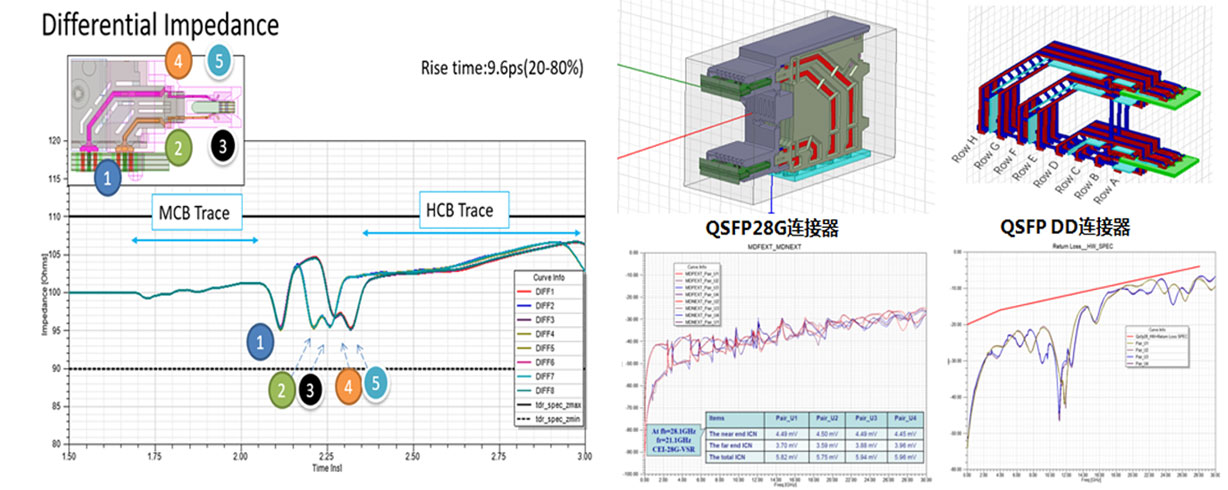

SI simulation: Use simulation software and high-performance servers to perform SI simulation on the 3D model of the connector, and optimize the structure when performance is insufficient.

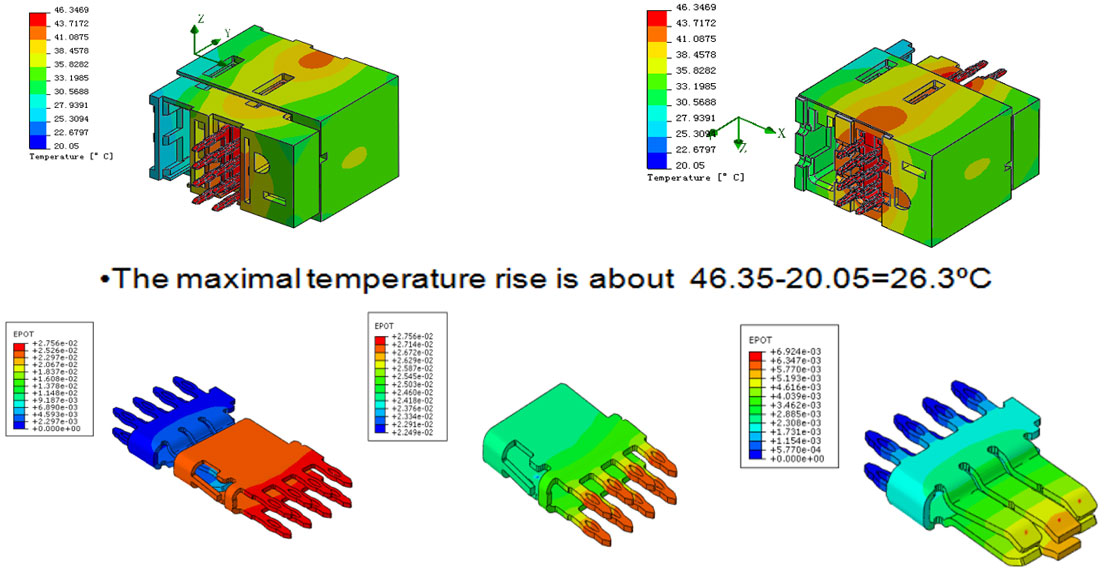

Temperature rise simulation: Use simulation software to simulate the temperature rise of the 3D model of the connector, and optimize the structure when the performance is insufficient.

Quality control

Reflow soldering

Insertion and extraction force test

Pixiv

Current tester

Salt spray tester

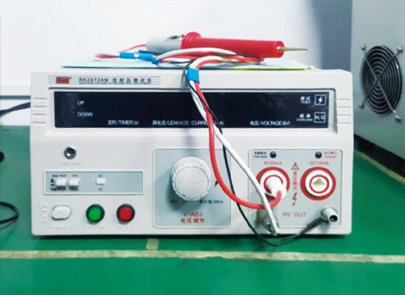

Hi-pot Tester

High and low temperature testing

Temperature rise tester

Hardness tester

Environmental tester

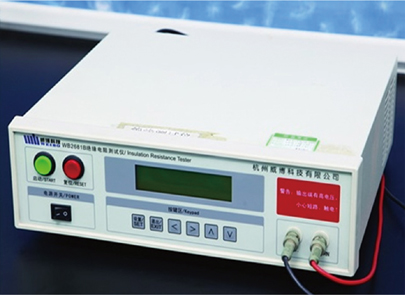

lmpedance tester

Film thickness tester

Manufacturing capacity

Mold workshop

Automation workshop two

Automation workshop

Dust-free assembly workshop

Stamping Workshop

Injection molding workshop

Customer service