What is a board-to-board connector?

Board-to-board connectors (BTB for short) are indispensable devices for power and signal coupling connections in precision circuits. As product complexity and circuit design scale continue to increase, board-to-board connectors are also developing in the direction of high speed, high power density, and thinness and lightness in line with market demand.

2. Classification and characteristics of board-to-board connectors

In actual use, we will consider which type of board-to-board connector to use based on usage scenarios, appearance structure, connection performance, overall cost and other aspects.

Pin header/pin header

Pin and female headers, also called headers, are the cheapest and most common connection methods.

Application scenarios: low-end, large-size smart devices, development boards, debugging boards, etc.

Advantages: Cheap and convenient, the hard connection is very stable, the overcurrent capability is strong, and it is convenient for wire welding and testing.

Disadvantages: large size, difficult to bend, large spacing, difficult to connect hundreds of pins.

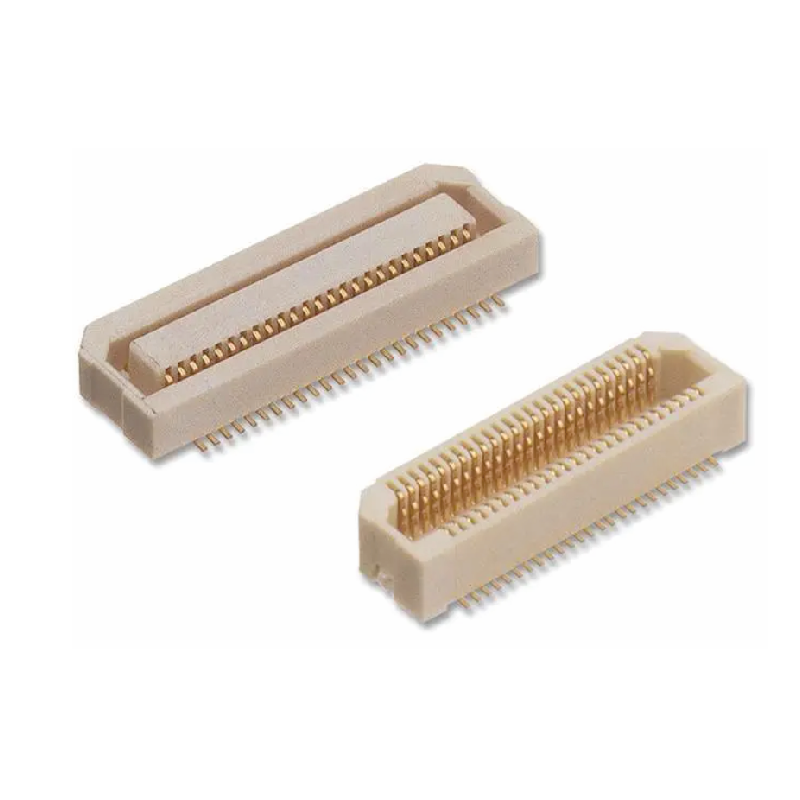

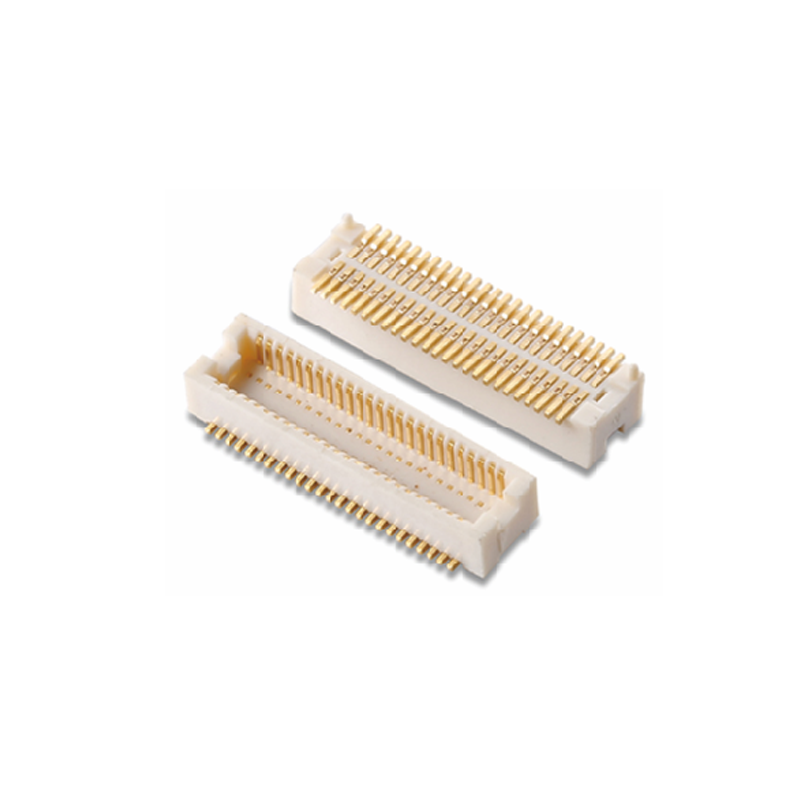

High-end board-to-board connectors

It is denser than pin headers and is widely used in compact products.

Application scenarios: It is basically used in conventional smart hardware products and is very widely used.

Advantages: Large number of pins and small size. A length of 1 cm can hold 40 pins (a power strip of the same size can only hold less than 20 pins).

Disadvantages: expensive, cannot be plugged in and out frequently, and the structural design needs to be fixed.

Thickened board-to-board connector

Board to board, board to wire, can be disassembled, can be combined, and can be inserted into the pin header.

Usage scenarios: development boards, test boards, large and fixed equipment (such as computer chassis wiring).

Advantages: Cheap, common, used with pin headers, very easy to connect and measure.

Disadvantages: Large size, difficult to fix, not suitable for mass production scenarios.

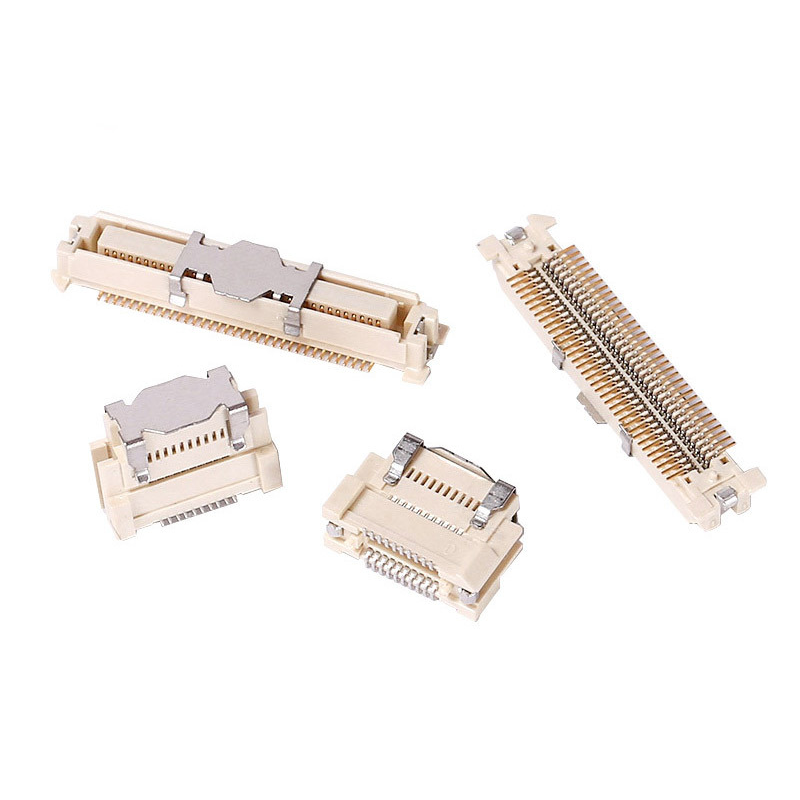

FPC connector plug/ZIF connector

Many smart hardware devices need to pull signals out of the motherboard. FPC is a good choice due to its bendability, small size, and changeable shapes.

Usage scenarios: connection between motherboard and sub-board, connection between motherboard and peripherals, lines that need to be bent, compact product space.

Pros: Compact and cheap.

3. How to select board-to-board connectors?

Connector structural dimensions

First, pay attention to the overall dimensions of the connector, and then pay attention to whether the installation space of the connector will interfere with other parts. Select the appropriate connector and fixing method according to the space size. For the connector itself, attention should be paid to the pin and pitch. The number of pins selected for the connector depends on the number of connected signals. For some patch-type connectors, the number of pins should not be too many. Because during the welding process of the chip placement machine, the connector plastic will be heated and deformed due to high temperature, and the middle part will bulge, causing the pins to be soldered.

Connector electrical properties

The electrical properties of the connector mainly include: limiting current, contact resistance, insulation resistance and electric strength, etc. When connecting a high-power power supply, you need to pay attention to the limiting current of the connector, make a derating design, and pay attention to the withstand voltage value between the pins.

When transmitting high-frequency signals (such as LVDS signals), attention must be paid to contact resistance. Connectors usually have low and constant contact resistance, generally ranging from tens of mΩ to hundreds of mΩ. For signals with impedance requirements, attention should be paid to impedance matching to avoid signal reflection.

Mechanical properties of connectors

The mechanical properties of the connector include pull-out force, pull-out frequency and mechanical anti-fooling, etc. Some signal interfaces require frequent plugging and unplugging. When selecting a connector, pay more attention to the connector's plugging force and number of plugs and plugs.

Mechanical foolproofing is very important for connectors. Once plugged in reverse, it is likely to cause irreversible damage to the circuit.

Connector Environmental Performance

For example, when the application environment is relatively humid, the requirements for the connector's moisture resistance and salt spray resistance are high, and it is necessary to ensure that the metal contacts of the connector are not corroded. In the field of industrial control, there are high requirements for the vibration and impact resistance of connectors to prevent the connector from falling off during vibration.